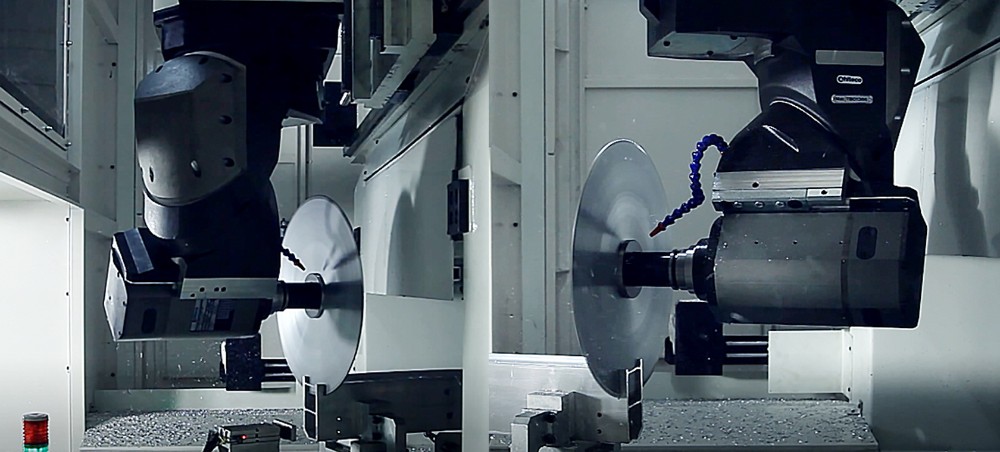

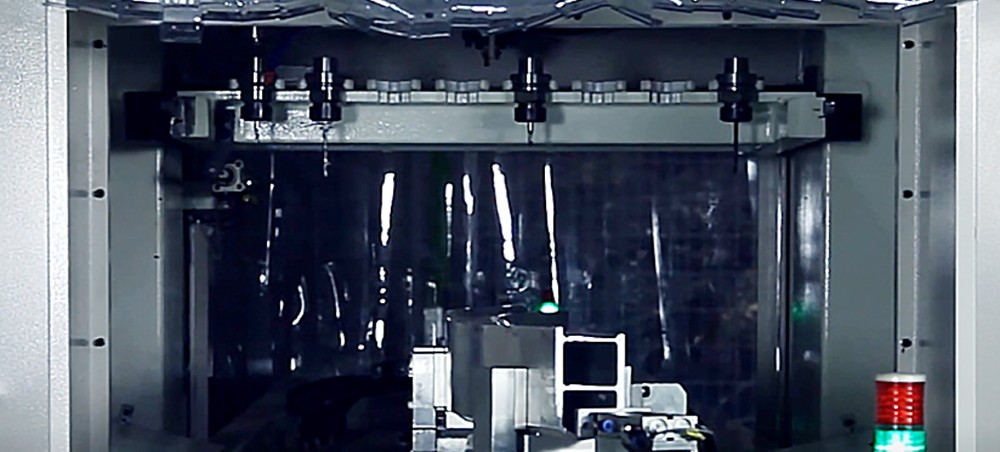

Five axis machining center

The five axis machining center has entered the field of door, window, curtain wall, and aluminum profile processing. It has been passively accepted and used following the development and application of materials. The application processing of fiveaxis CNC equipment has now become very popular. There are processing requirements for large-section workpieces such as sun rooms, corners of unit curtain walls and columns of frame curtain walls. The process holes of some components must be processed using a five axis machining center.

The characteristic of the gantry type machining center is the processing width, while the vertical type is characterized by easy clamping of materials and convenient spindle feed. These are in line with the changing processing needs of aluminum curtain wall profiles, so Fenstek's five axis machining center generally adopt a gantry structure.

Fenstek five axis machining center adopts high-quality imported servo motor, ball screw, linear guide, bearings and other components to ensure that the equipment has a high processing accuracy, high stability and reliability. The feeding movement is pre-stretched to ensure the stability of the machining accuracy.

中 文

中 文 Japanese

Japanese Spanish

Spanish Russian

Russian Arabic

Arabic Portuguese

Portuguese French

French Korean

Korean Vietnamese

Vietnamese Thai

Thai