Multi-layer welding of UPVC Window :How to ensure exceptional consistency in the welding results of

In today's UPVC window manufacturing industry, where both efficiency and quality are highly valued, customers' demands for production capacity are continuously increasing. To meet this market demand, multi-layer four point welding technology has emerged, gaining widespread recognition for its efficient production capabilities. However, as the number of layers increases, ensuring consistent welding results for each layer of window frames has become a major challenge for manufacturers. Fenstek, a leader in the field of UPVC window equipment, fully understands the importance of this challenge. Therefore, we have made numerous innovative upgrades to our four point welding machines to ensure that each layer of window frames achieves exceptional welding results during multi-layer welding.

1.Independent datum design to ensure welding independence

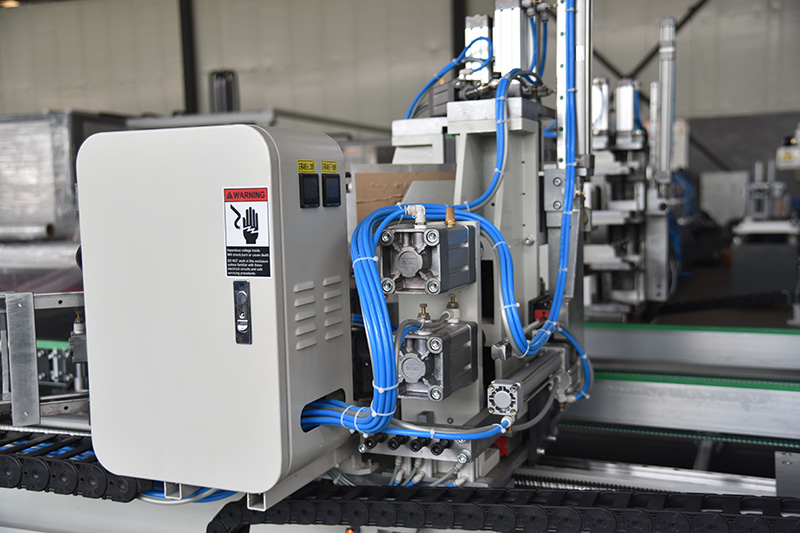

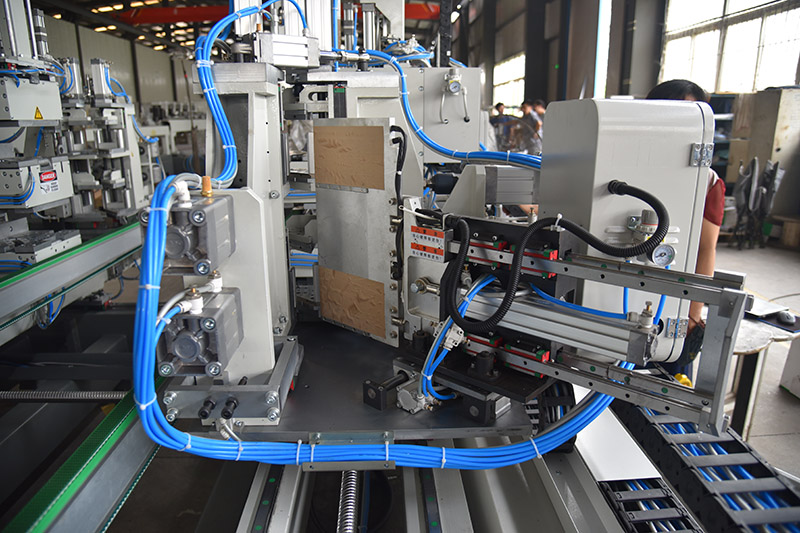

Unlike traditional multi-layer welding methods that use welding backing plates, Fenstek's four point welding machines adopt a unique independent datum design. Each welding platform is like an independent building with its own datum plane. This design ensures the independence of each layer of welding, effectively avoiding interlayer interference, and thus guarantees the consistency of welding results for each layer of window frames.

2.Double-layer independent clamping to enhance welding stability

To further enhance welding stability, Fenstek has equipped its welding machines with clamping linkage devices. This device ensures that double-layer window frames maintain a stable position during the welding process, preventing welding defects caused by movement or deformation. The double-layer independent clamping design provides sufficient support and fixation for each layer of window frames, thereby improving the overall quality of welding.

3.Special feed cylinder to ensure top-layer welding results

Fenstek also goes all out in terms of top-layer welding. We have specially equipped a special feed cylinder for controlling the welding process of the top layer. This cylinder can precisely control welding speed and pressure, ensuring that the top-layer window frame is fully fused and solidified during the welding process. Through this design, Fenstek has successfully solved the problem of poor top-layer welding results, making each layer of multi-layer welding achieve the desired welding results.

In summary, Fenstek has successfully addressed the challenge of ensuring consistent welding results for each layer in multi-layer four-corner welding through innovative upgrades such as the independent datum design, double-layer independent clamping, and special feed cylinder. Our equipment not only meets customers' high demands for production capacity but also achieves exceptional improvements in welding quality.

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인