Assembly of steel reinforcement

There are mainly two methods for assembly of steel reinforcement.

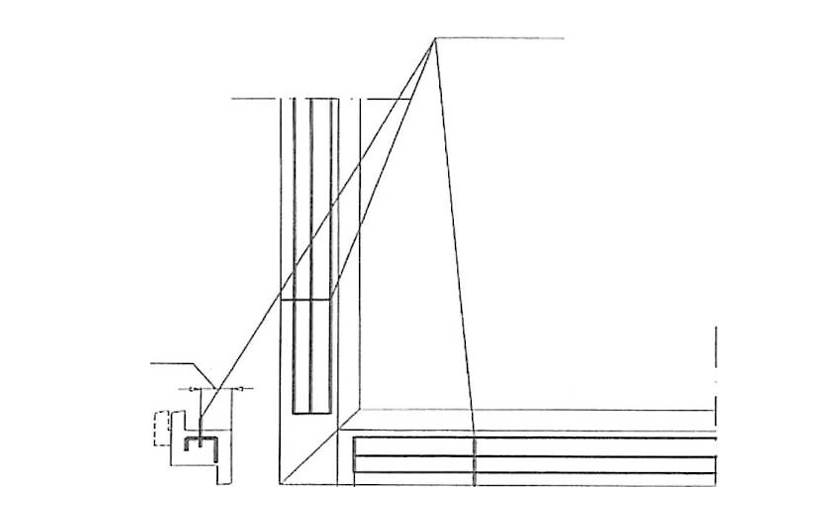

(1) Insert the steel reinforcement in advance if it will not affect the welding position.

(2) Insert the steel reinforcement after joining profiles together at cross or T welding position.

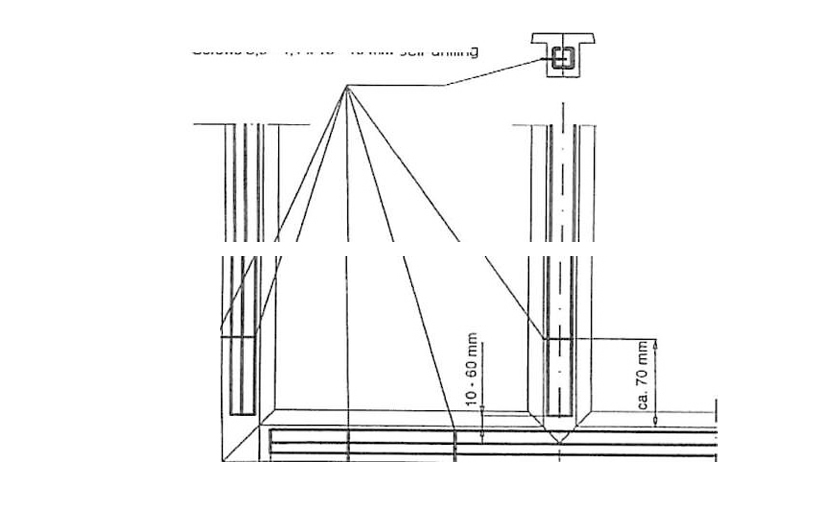

The It is recommended to choose self-tapping and self-drilling screw as the fastener between the steel reinforcement and the profile. Round-head screw may be used, but not self-plugging rivet. The fasteners used to fix every steel reinforcement should be no less than 3, with a gap ^300mm and distance from the steel reinforcement <100mm. The steel reinforcement should not come loose after fixing.

Steel cuts in the case of mechanically set transom/mullions align themselves to the corresponding connectors. The screw fixings of the connectors have a general to occur in steel. (See Transom/Mullion connection). The reinforcing of the residential door sash should be screwed together diagonally in the glazing rebate range at intervals of 200mm.

The profile interior should be free from any scratch or deformation after the steel reinforcement is installed into the steel reinforcement cavity and the installation of driver handle and door lock is not affected. When the steel reinforcement does not match the profile in dimension, do not install the steel reinforcement forcibly.

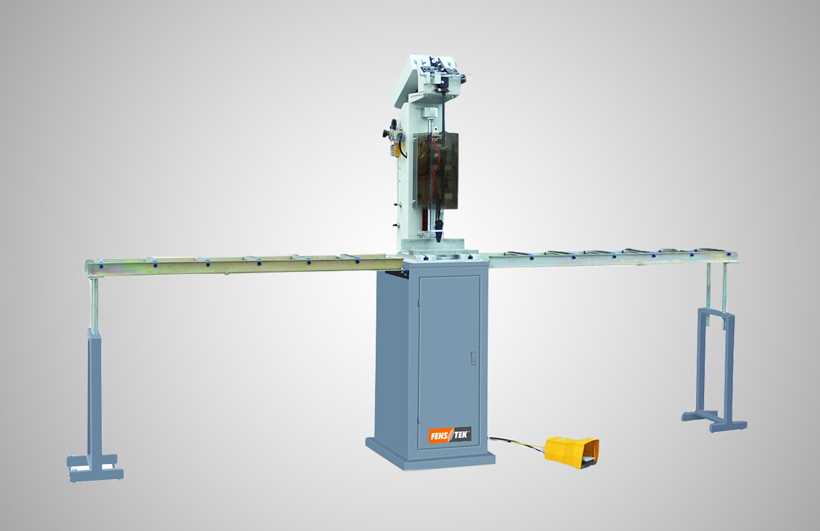

The steel reinforcement is installed by the Auto Screw Driver Machine,Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds. Integrated screw feeding system and automatic start of the hopper movement when operating.

There are mainly two methods for assembly of steel reinforcement...

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인