FENSTEK Industry Knowledge 1-2:Storage of UPVC Profiles

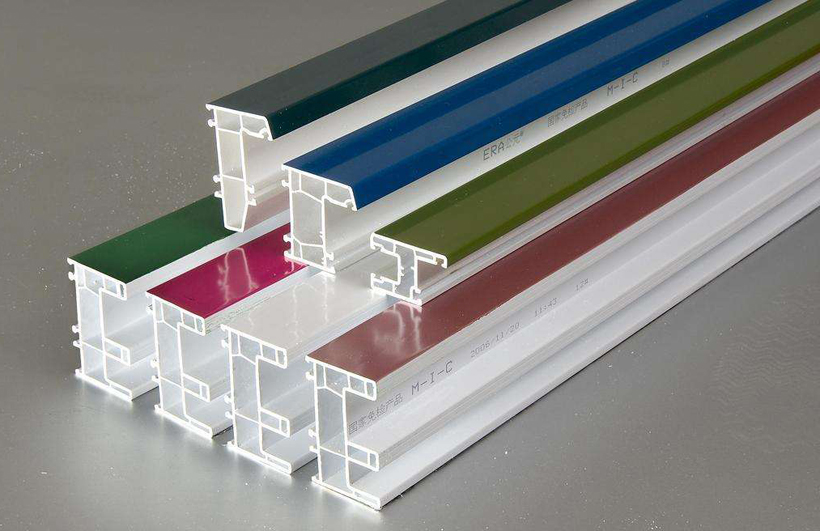

The UPVC profiles are delivered with a protective foil which is to be removed immediately after installation. The delivery occurs in pallets; bundled goods packaged in foil is also possible. During delivery of the products, attention is to be paid concerning the completeness and integrity of the packaging. Profile damage incurred during transits and not recorded shortages are to be reported immediately. The corresponding reservations are to be carried out on the transport documents. The profiles must not be slid nor flung during transport and while handling. They are to be stored set into each other in such away that a deformation is impossible.

Simple storage in the open air is to be avoided as far as possible in order to prevent processing difficulties through pollution and humidity. If open air storage is unavoidable, the profiles must be conditioned by introducing to the workshop temperature 24 hours before processing time and longer in warmer climates such as the Caribbean, Mediterranean, South America, Florida and the like. Note the ends of the packaging are to be opened in this case as the profiles can heat up 1°C per hour approx. The processing temperature should be at least 17°C.So when welding by FENSTEK upvc window welding machine,the welding result can be gurranteed.

When storing profile bundles must lay surface flat over their whole lengths. The bundle stackheights must not exceed 100 cm. An uneven storage on crosswood or similar, brings a bending of the profiles which cannot be eliminated. Shelves, whose support distance is less than 100cm but have full shelf bottoms, have proven themselves, e.g. with a plate material. And this also applies to parts already cut, but not yet welded must not under anv circumstances be subject to thermal radiation e.g. sunbeams, radiant heat or air heaters .

The UPVC profiles are delivered with a protective foil which is to be removed immediately after installation.

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인