FENSTEK Industry Knowledge 1-3:Cutting profiles to size

FENSTEK Industry Knowledge 1-3:Cutting profiles to size

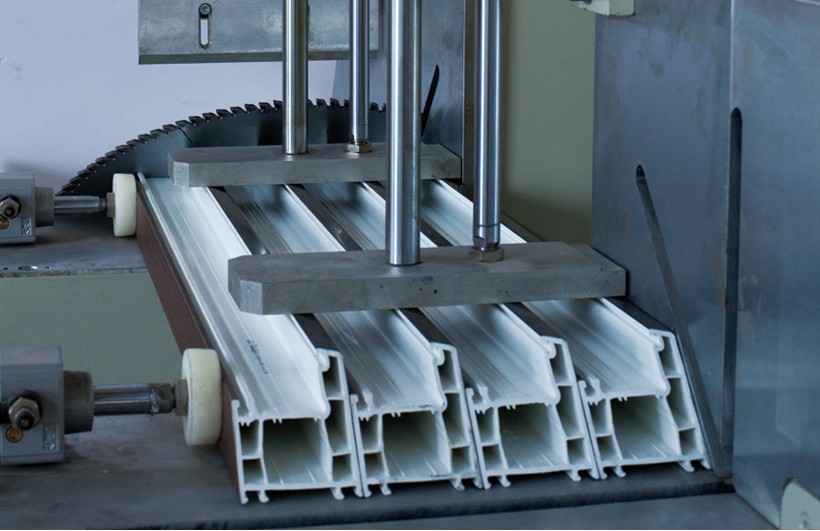

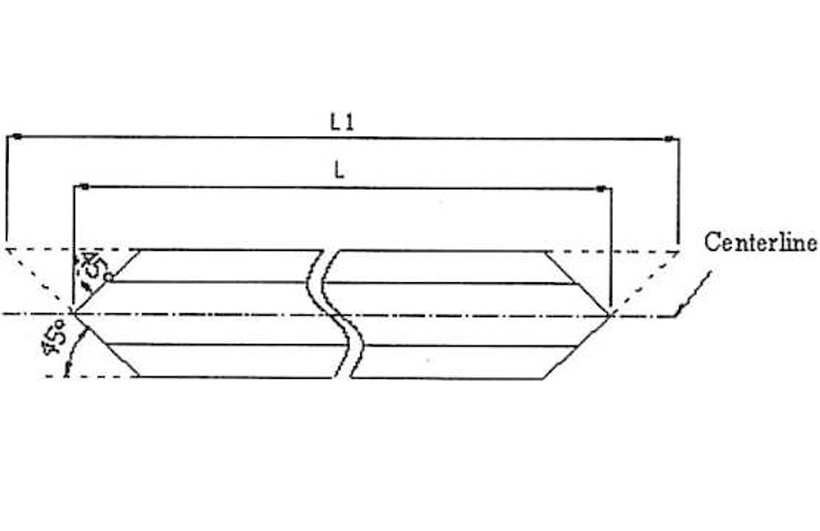

An exact cut is a prerequisite for an optimal weld. This applies both to the mitres as for any routing operations. Care must be taken that the cross section is not only cut at a 45° angle, but also 90° vertical by the double head cutting saw or single head cutting machine in angle i.e. adapted to the sloping elements. For the cut of plastic window profiles, carbide-tipped saw blades with a negative tooth angle have proved effective. Saw blades with which different materials are processed are unsuitable. Layout tables on both sides of the cutting saw are useful, they should be adjusted precisely with the cutting support of the machine; this also applies to the angular support of the profiles. While cutting the profiles, no lubricating or cooling materials should be used since these can damage weldability. Attention must be paid to angle alignment when checking and cutting. Cut pieces must be stored in such a way that the mitres are not damaged.

Preparation of profiles for frame and sash

The profiles for outer frame and sash are cut on Double Mitre Saw and Single Mitre Saw. Cutting operation needs to follow strictly the FENSTEK Machinery's User Manual.

The following factors should be taken into account:

• Design drawing

• Customers' requirements

• Opening dimension

• Cutting machine's setting

Some upvc window cutting machines themselves include welding allowance in the cutting length, therefore, the welding allowance can be neglected when setting cutting length on the machines, and the profiles can be cut to structural member's size directly. If cutting machines themselves do not include welding allowance in the cutting length, the cutting dimension should be that of the original dimension of the structural member plus the welding allowances at two ends (Generally, the welding allowance on each end is 3mm).

An exact cut is a prerequisite for an optimal weld. This applies both to the mitres as for any routing operations.

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인