Industry Knowledge 1-6:Milling of hardware hole and mounting grove

Industry Knowledge 1-6:Milling of hardware hole and mounting grove

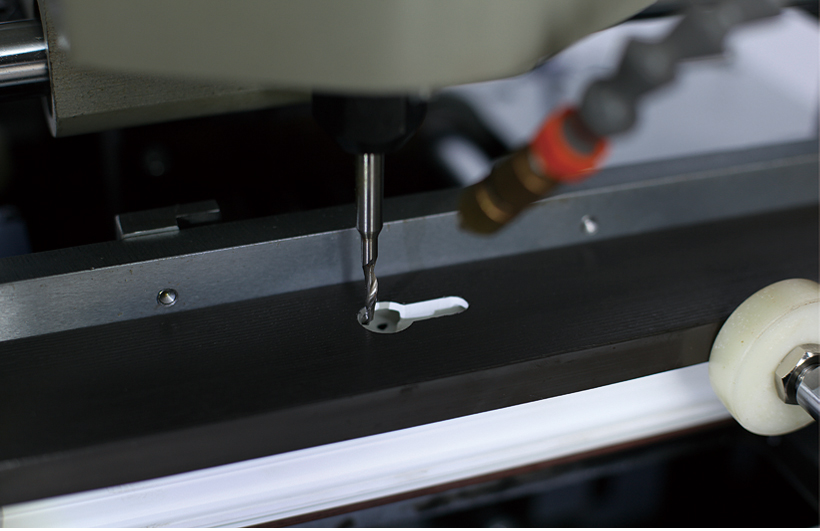

Lock hole and mounting groove are milled on the lock hole milling machines.

It might be necessary to change tools and adjust feed amount in accordance with the hole size during actual machining in order to mill grooves and holes. For example, when milling holes for multi-point handle, you will use a <t>12 milling tool for the middle hole and 2 <t>10 ones for bores at two sides. Attention should be paid as so not to misuse the tools. After milling, the bore should be at correct position, smooth at its perimeter, free from burrs and convenient for installation of the driver.

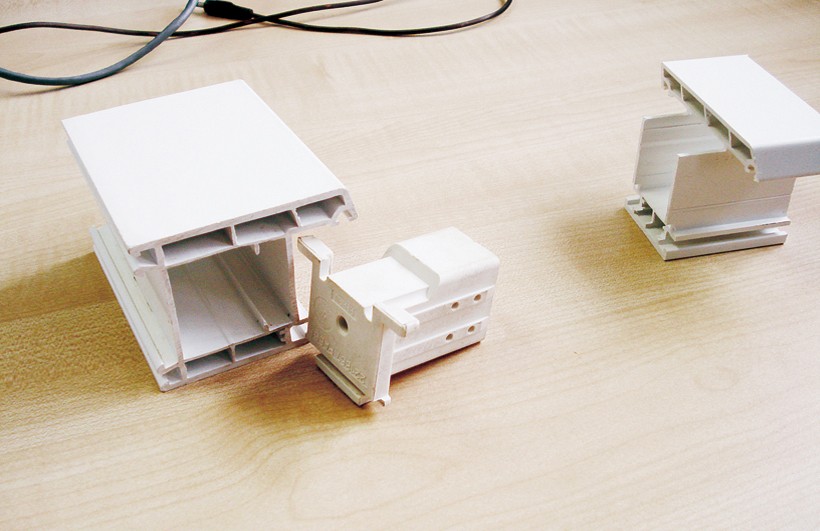

End milling of mullion/transom for mechanical jointing

When mullion or transom is constructed by means of mechanical jointing, the end of the mullion or transom profile needs to be milled to according shape to match the structural profile. End milling is completed on a milling cutter by the end milling machine. Milling cutters must be those manufactured for the specific profile and machinery upon which they are mounted.And besides,Fenstek also provide the 5 cutter end milling machine means that no need to change cutters,It will help to save cost.

Lock hole and mounting groove are milled on the lock hole milling machines...

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인