Industry Knowledge 1-6:Milling of drainage hole and air equalizer hole

Milling processes involved in UPVC window and door fabrication can be placed into 3 categories.

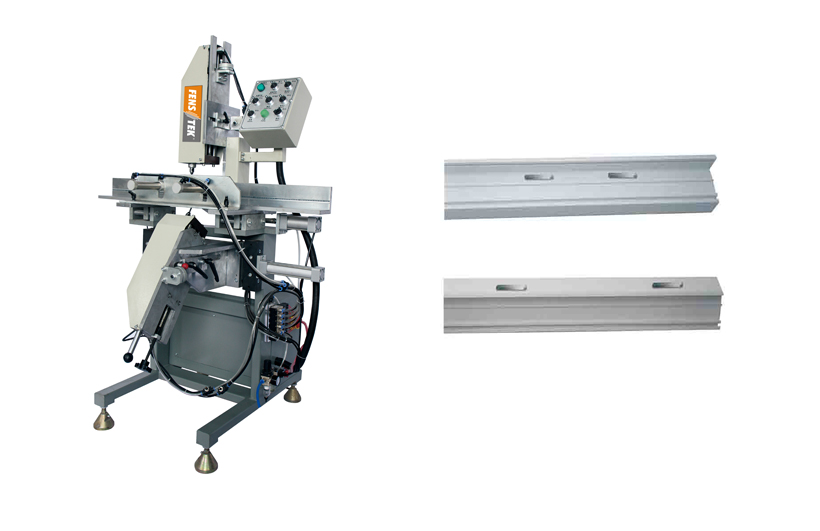

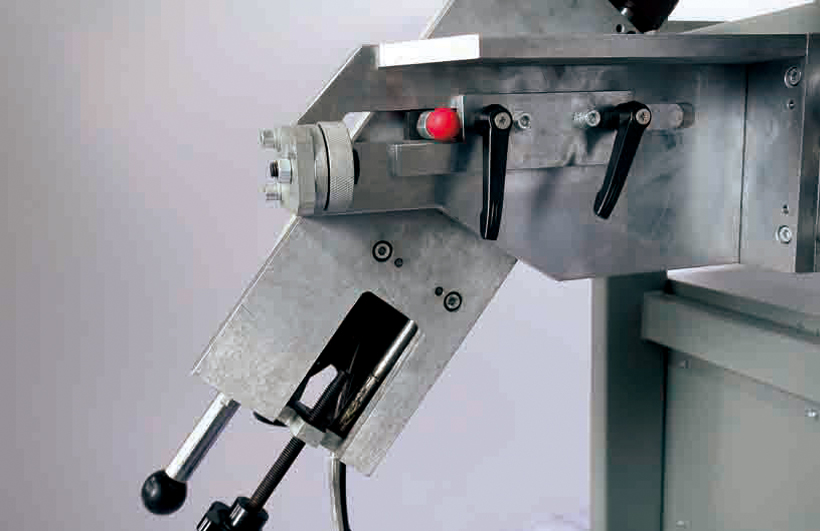

・ Milling of drainage hole(water slot hole) and air equalizer hole

・ Milling of hardware hole and mounting grove

・ End milling of mullion/transom for mechanical jointing

These process is completed by UPVC Window Water Slot Milling Machine,UPVC Window Lock Hole Milling Machine ,CNC Copy Routing Machine,End Milling Machine etc.

Milling of drainage hole (water slot holes)and air equalizer hole

It is requirement of UPVC profiles that adequate means be provided for the drainage of water and for the passage of air in order to facilitate with this drainage, (i.e. pressure equalisation). Drainage holes(water slot holes) that are drilled on UPVC windows and doors enable the accumulated water inside the windows and doors to be drained out and then watertightness is achieved. To obtain a pressure equalisation and ensure water to drain out smoothly, it is beneficial to position air equaliser holes in the upper or vertical side of the windows and doors.

Glazing beads must be cut to exact lengths by the high precision Glazing Bead Cutting Machine, this alone does not guarantee full weathertightness. It is advisable to seal the joints with a suitable sealant.

Outer frames, sashes, and transoms must be drained in the range of the water collecting chambers as well as ventilating, in a manner that a back-pressure is avoided. Based on their locations and functions, the drainage holes and air equaliser holes could be classified as interior and exterior drain holes as well as interior and exterior air equaliser holes.

Milling processes involved in UPVC window and door fabrication can be placed into 3 categories...

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인