Preparation before welding the upvc window

Preparation before welding the upvc window

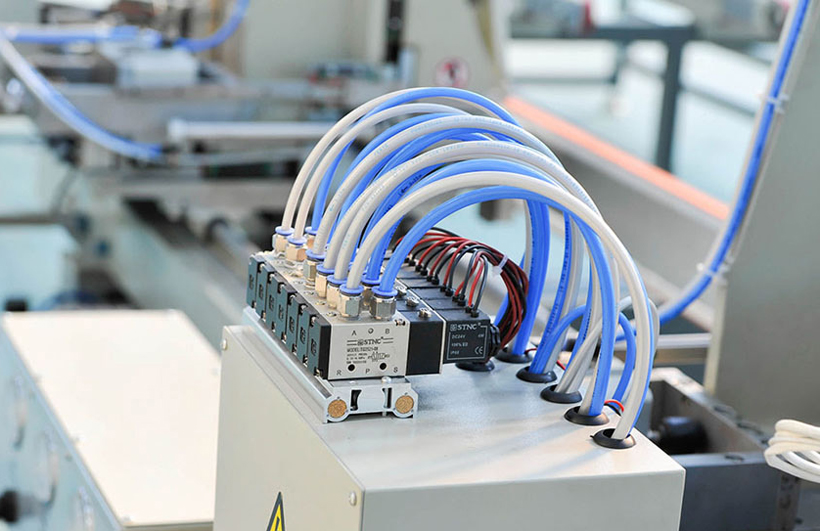

1.Check for the upvc window welding machine's normal power supply and air pressure and that the value of each pressure gauge is within the permissible working scope. Switch on the heating pad 20~30minutes in advance for preheating after the machine is on.

2. The atmospheric temperature should be above 180 when welding the upvc window profile and the profiles should be left at room temperature for 24 hours before welding so that the temperature between the profile and heating pad decreases by gradients and corner strength is increased.

3. Select and adjust the baffle and adjust welding time, temperature and pressure based on the frame and sash.

4. The weldment should be marked and stored as regulated. Be ware of position of mounting hole, hinge, handle and drain hole to prevent wrong welding.

5. Don't weld the sealing strip, rubber strips and protection film into welding seam. Please refer to the sealing strip part for preparation of sealing strips and rubber strips. Shear off the welding allowance on the protection film at the welded part along the welding seam and ensure that the protection film is not melt into the welding seam.

By FENSTEK Window Machinery.

Check for the upvc window welding machine's normal power supply and air pressure and that the value of each pressure gauge is within the permissible working scope...

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인