The advantages of aluminum window cutting and milling center

The advantages of aluminum window cutting and milling centers are primarily manifested in the following aspects:

- Enhanced Processing Accuracy and Efficiency

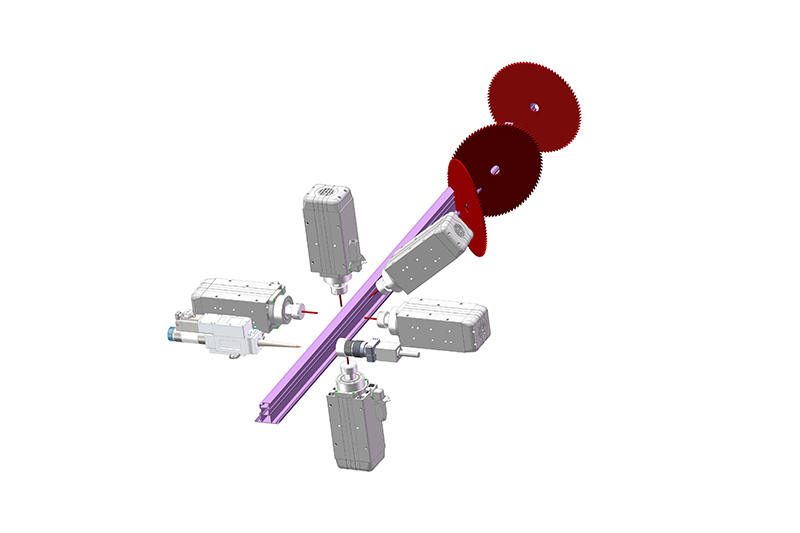

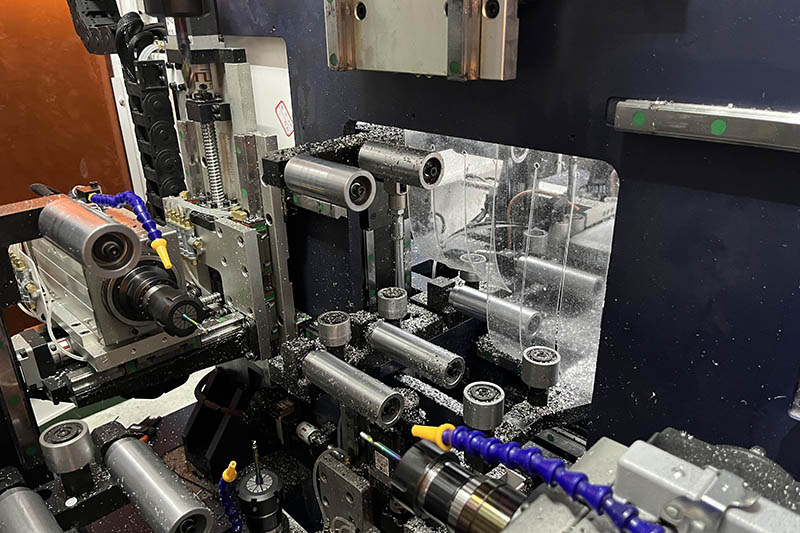

- High-Precision Processing: Leveraging numerical control technology, these centers achieve high-precision cutting, drilling, milling, and other processes, fulfilling the stringent dimensional and shape requirements of aluminum doors and windows.

Boosted Production Efficiency: Automated processing significantly reduces manual operation time, enhancing overall productivity. Moreover, the equipment accommodates multi-step processes, completing them in a single machine for time and efficiency gains.

- Reduced Production Costs

- Minimized Labor Needs: Highly automated equipment mitigates the reliance on skilled workers, thereby decreasing labor costs.

- Improved Material Utilization: Precise numerical control processing minimizes material waste and enhances material utilization, further lowering production costs.

- Strong Flexibility and Adaptability

- NC Programming: Through numerical control programming, these centers swiftly adapt to processing demands for aluminum doors and windows of varying specifications and shapes, fostering production flexibility and adaptability.

- Intelligent Recognition and Adjustment: Some equipment is equipped with intelligent recognition of profile data (e.g., height, wall thickness) and can automatically adjust processing parameters (e.g., feed speed, feed position), further enhancing flexibility and adaptability.

- Elevated Product Quality

- Consistency and Repeatability: The consistent and repeatable nature of numerical control processing ensures stable product quality.

Additional Functions: Features like laser marking, automatic maintenance reminders, etc., contribute to further improving processing accuracy and quality.

- Facilitated Management and Maintenance

- Network Connectivity and Monitoring: Many centers are equipped with network connectivity, enabling data exchange and information sharing with production management systems, Enterprise Resource Planning (ERP) systems, and more, facilitating real-time monitoring and remote management of production processes.

- Automatic Maintenance Reminders: Some equipment comes standard with automatic maintenance reminders, preemptively addressing potential issues and enhancing equipment availability and longevity.

- Environmental Protection and Energy Conservation

- Automated Chip Removal and Dust Collection: Equipped with chip removers and dust collectors, these centers minimize cleaning frequency, maintaining a clean production environment and complying with environmental regulations.

In summary, aluminum window cutting and milling centers, with their advantages of high precision, efficiency, low cost, strong adaptability, and ease of management, have been widely applied in the aluminum door and window processing industry, driving the industry's transformation and upgrading.

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인