What is PVC Window Welding Machine

In the realm of modern window manufacturing, PVC (Polyvinyl Chloride) windows have emerged as a popular choice due to their durability, energy efficiency, and cost-effectiveness. At the heart of producing these high-quality PVC windows lies the PVC window welding machine, a vital piece of equipment that ensures precision, strength, and aesthetic appeal in the final product.

What is a PVC Window Welding Machine?

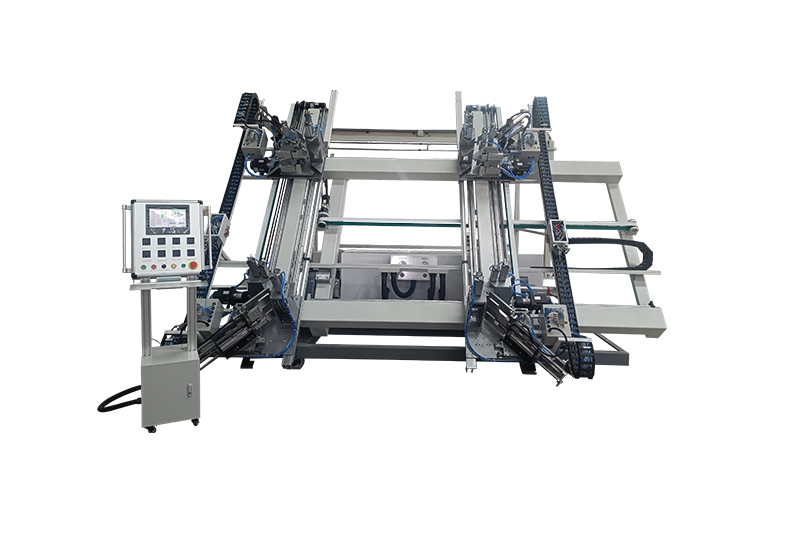

A PVC window welding machine is a specialized tool designed to join PVC profiles used in the construction of windows and doors. These machines utilize heat to soften the PVC material at specific points, allowing the profiles to be fused together seamlessly. The welding process creates a strong, watertight bond that ensures the structural integrity and longevity of the window.

Types of PVC Window Welding Machines

There are several types of PVC window welding machines available in the market, each tailored to meet specific production needs and requirements. Some of the most common types include:

Semi-Automatic Welding Machines: Semi-automatic machines automate certain aspects of the welding process, such as temperature control and material feeding, while still allowing for some manual intervention. They offer a balance between efficiency and flexibility, making them a popular choice for medium-sized production facilities.

Fully Automatic Welding Machines: Fully automatic welding machines are designed for high-volume production, automating the entire welding process from start to finish. These machines are equipped with advanced control systems that ensure consistent welding quality and significantly reduce labor costs.

Key Features and Benefits

Precision and Consistency: PVC window welding machines ensure precise and consistent welding results, eliminating the need for manual adjustments and reducing the risk of errors.

Efficiency: Automated and semi-automated machines significantly increase production speed, allowing manufacturers to produce more windows in less time.

Durability: The strong, watertight bonds created by PVC window welding machines ensure that the windows are durable and long-lasting.

Versatility: Modern welding machines can be configured to weld a variety of PVC profiles, making them suitable for a wide range of window designs and sizes.

Cost-Effectiveness: While the initial investment in a PVC window welding machine may be significant, the long-term cost savings in terms of increased production efficiency, reduced labor costs, and improved product quality make them a cost-effective solution for window manufacturers.

Conclusion

PVC window welding machines are an essential tool for modern window manufacturing. Their precision, efficiency, and versatility make them a valuable asset for manufacturers looking to produce high-quality, durable PVC windows. As the demand for energy-efficient and cost-effective building materials continues to grow, the role of PVC window welding machines in the construction industry will become even more important.

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인