Industry Knowledge 1-4:Profile preparation for cutting mullion

Profile preparation for mullion

There are mainly two methods to construct mullions and transoms: welding jointing and mechanical jointing. Under the circumstances the mullion is constructed by means of welding, the mullion profile needs to be cut with a 90°wedge, which can be done on Double Mitre Saw, Single Mitre Saw, and Mullion Saw.

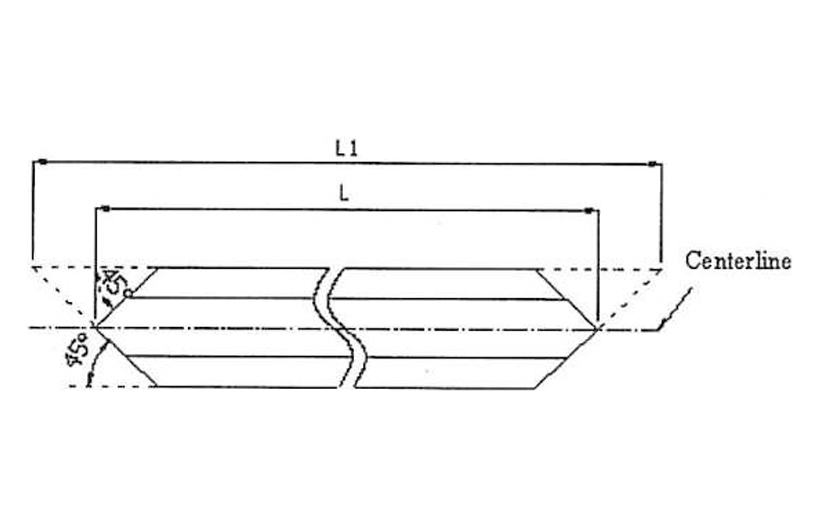

When the mullion profiles are cut on the Double Mitre Saw, the structural members should meet the following technical requirements: Please refer to Figure 1-1:

⑴ The profile's end angle is 45°after the first cutting, with an allowance of ±0.5°,

⑵ The profile's end angle is 90°after the second cutting, with an allowance of ±0.5°.

(3) The deflection allowance between the profile's end sharp corners with the centreline is ±0.5mm.

(4) The length of profile prepared is in accordance with the design requirements with an allowance of ±0.5mm.

(5) The perpendicularity of the structural member's cutting faces and the profile's two sides is guaranteed. The welding surface is clean and free from dirt, water, grease, scraps and other foreign matters.

There are mainly two methods to construct mullions and transoms: welding jointing and mechanical jointing......

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인