How to select the upvc window welding machine?

When selecting the upvc window welding machines, one should pay attention to the following adjustment possibilities:

Heating plate temperature

Melting pressure

Melting time Cooling time Joining pressure /clamping pressure Course limitation at melting time and melting pressure.

Since the exact weld process is of exceptional importance for later fabrication as well as the long time behaviour of the weld, the following rules must be considered:

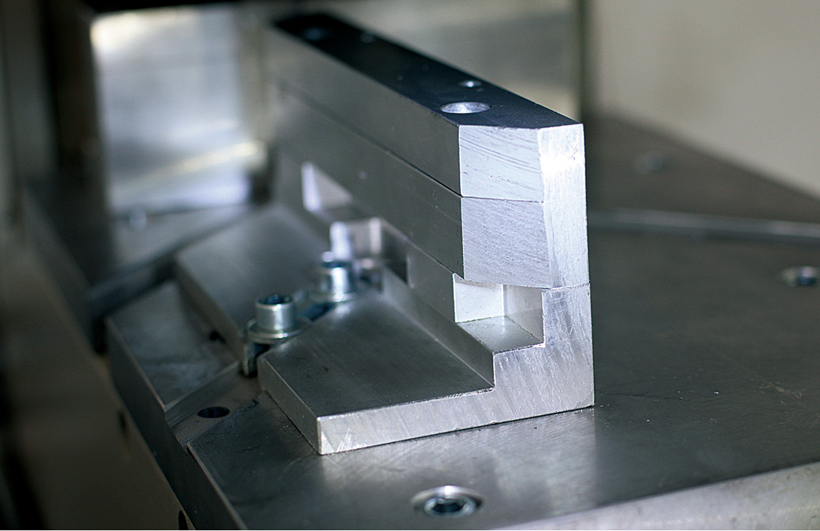

1.The cut profiles are, with the aid of profile dependent support blocks, set to the stops of the welding machine, to be noted is that the support blocks should be tightly mounted. The clamping pressure must be adjusted in such a way that the profiles during the subsequent welding process do not slip and are not deformed.

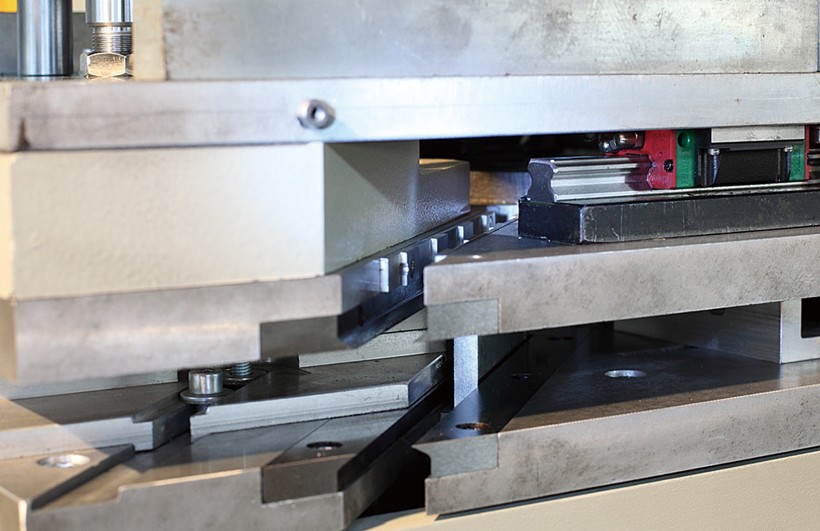

It is important that both clamping plates are adjusted uniformly. Ajambing of the profiles must be avoided.

2.The welding foil must be kept free of any contaminants. The welding foil should be regularly cleaned with non-synthetic cloth or industrial tissue.

3.The welding plates are to be checked periodically for correct temperature in order to hold weld quality constant. Suitable checking apparatus is available in specialist shops. Teflon coating of the plate must be monitored regularly. As soon as burning signs and/or wear and tear appears, it is to be re-newed.

4.Important with the welding process is the precise regulation and compliance with the plasticizing time, which can be different depending on machine type,for example four head welding machine or four point welding machine

When selecting the upvc window welding machines, one should pay attention to the following adjustment possibilities...

中 文

中 文 Русский

Русский عربي

عربي Español

Español Português

Português Français

Français แบบไทย

แบบไทย Tiếng Việt

Tiếng Việt 日本語

日本語 한국인

한국인