Industry Knowledge 1-5:Profile preparation for V notch

V notch will be required when a mullion or transom is constructed by means of welding jointing, which is cut on FENSTEK V-cutting saw.

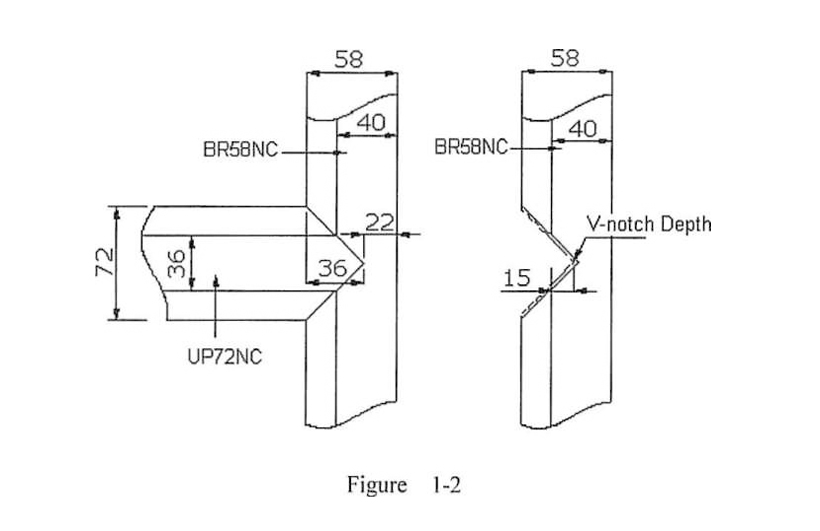

When the windows and doors are fabricated in accordance with the dimensions on the design order, the depth of V notch in small face of the profile is: half of the small face width of the mullion to be welded minus the welding allowance. For example, when a Suntec 60 series profile is welded with UP72NC, the depth of V notch on BR58NC's small face is 36/2-3=15mm. The cutting of V notch is shown as Figure 1-2.

All structural members must meet the following technical requirements after cutting.

(1) Angle allowance for V notch after cutting: ±0.3°.

(2) Depth allowance for V notch after cutting: ±0.5mm.

(3) The perpendicularity of the structural member's cutting faces and the profile's two sides is guaranteed. The welding surface is clean and free from dirt, water, grease, scraps and other foreign matters.

Calculation of profile prepared for windows and doors

When calculating the profiles prepared for windows and doors, the following factors should be taken into consideration:

• original dimension of windows and doors

• overlap between the frame and sash

• welding allowance

Then, the lengths of all structural members are calculated in accordance with the matching relation between the frame and sash.

V notch will be required when a mullion or transom is constructed by means of welding jointing, which is cut on V-cutting saw...

中 文

中 文 Japanese

Japanese Spanish

Spanish Russian

Russian Arabic

Arabic Portuguese

Portuguese French

French Korean

Korean Vietnamese

Vietnamese Thai

Thai